|

|

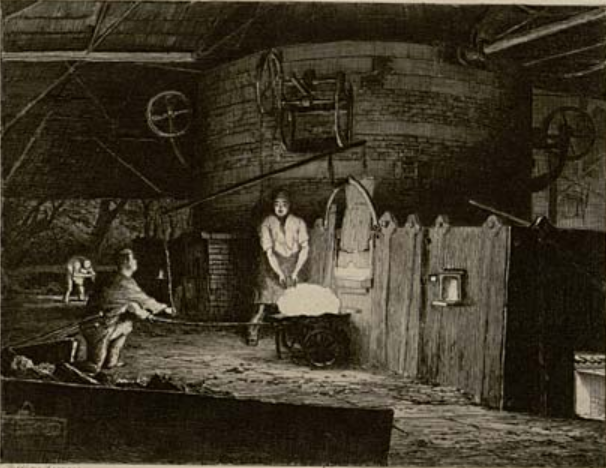

Occupation: Puddler |

|

|

Puddling was one step in one of the most important processes of making the first appreciable volumes of high-grade bar iron(malleable wrought iron) during the Industrial Revolution. In the original puddling technique, molten iron in a reverberatory furnace was stirred with rods, which were consumed in the process. It was one of the first processes for making bar iron without charcoal in Europe, although much earlier coal-based processes had existed in China. Eventually, the furnace would be used to make small quantities of specialty steels. Though it was not the first process to produce bar iron without charcoal, puddling was by far the most successful, and replaced the earlier potting and stamping processes, as well as the much older charcoal finery and bloomery processes. This enabled a great expansion of iron production in Great Britain, and shortly afterwards, in North America to take place. That expansion constitutes the beginnings of the Industrial Revolution so far as the iron industry is concerned. Most 19th century applications of wrought iron, including the Eiffel Tower and the Victorian era bridges and the original framework of the Statue of Liberty used puddled iron. |

|

The opinions and ideas on here are my own, but no man is a island - no woman either - therefore I have referred to work by others. No copyright infringement is intended in any of the material I have uploaded onto my site. Please contact me if I have failed to acknowledge any of your work and I will rectify the situation or remove the offending material.. |

An iron puddler or (often merely puddler) is an occupation involved in the manufacture of iron.

An iron puddler or (often merely puddler) is an occupation involved in the manufacture of iron.